Corporate Profile

NIRA is a trusted name in the food processing industry, proudly creating a wide range of quality products including all types of spices, biscuits, and cold drinks. With a strong commitment to taste, hygiene, and innovation, NIRA delivers excellence in every bite and sip. Our extensive manufacturing capabilities are built to serve diverse consumer needs while ensuring premium quality and maximum customer satisfaction.

NIRA TASTY Company Strategy

- Purpose: To lead the food processing sector by offering exceptional quality, fostering innovation, and building lasting customer trust.

- Vision: To become a globally recognized brand in the food processing industry by maintaining the highest standards of quality, hygiene, and innovation.

- Mission: To consistently deliver premium spices, biscuits, and cold drinks that satisfy the taste and trust of every household, while fostering sustainable practices and customer-centric values.

NIRA TASTY Core Values

- Quality First: We ensure the finest ingredients and maintain strict hygiene in every stage of production.

- Customer Commitment: We build long-term relationships by exceeding customer expectations through service and taste.

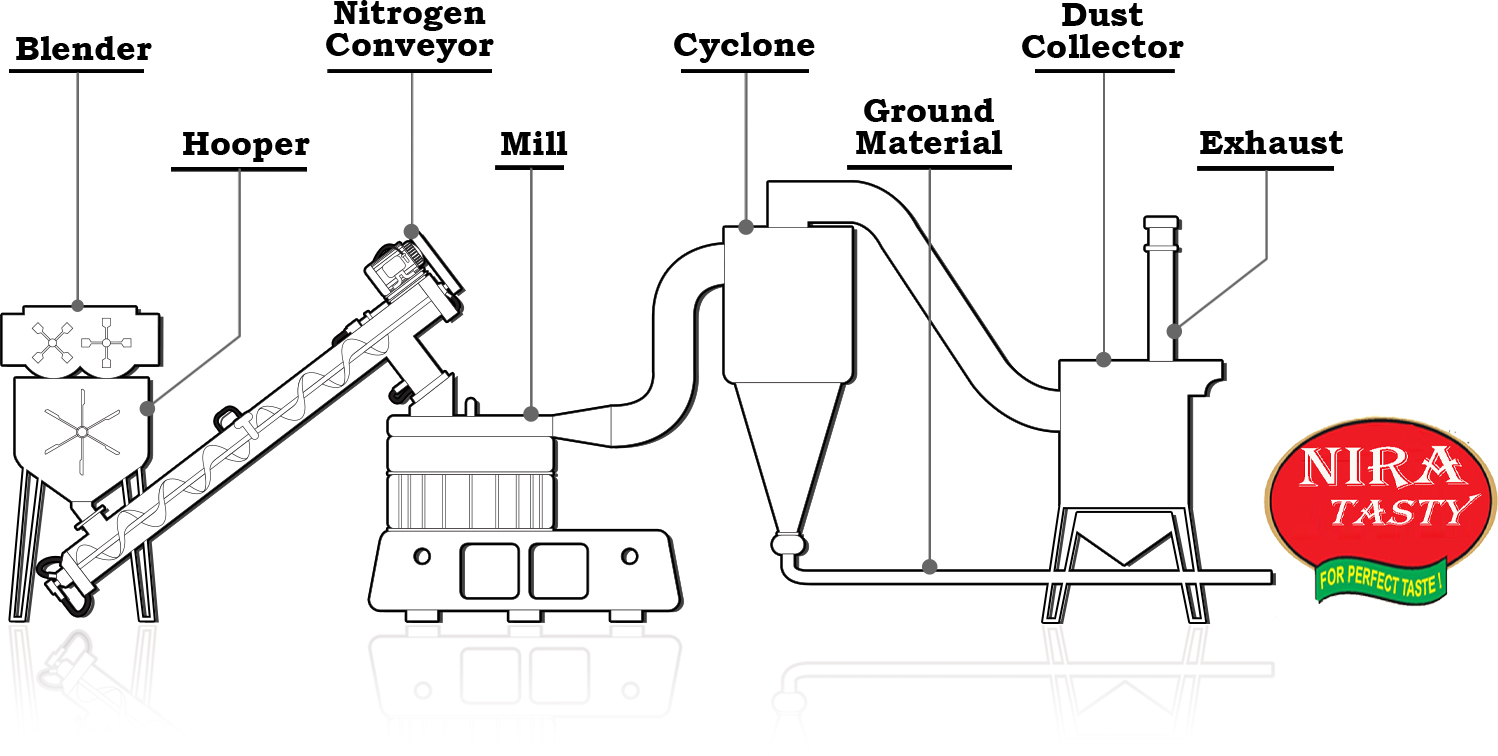

CRYOGENIC

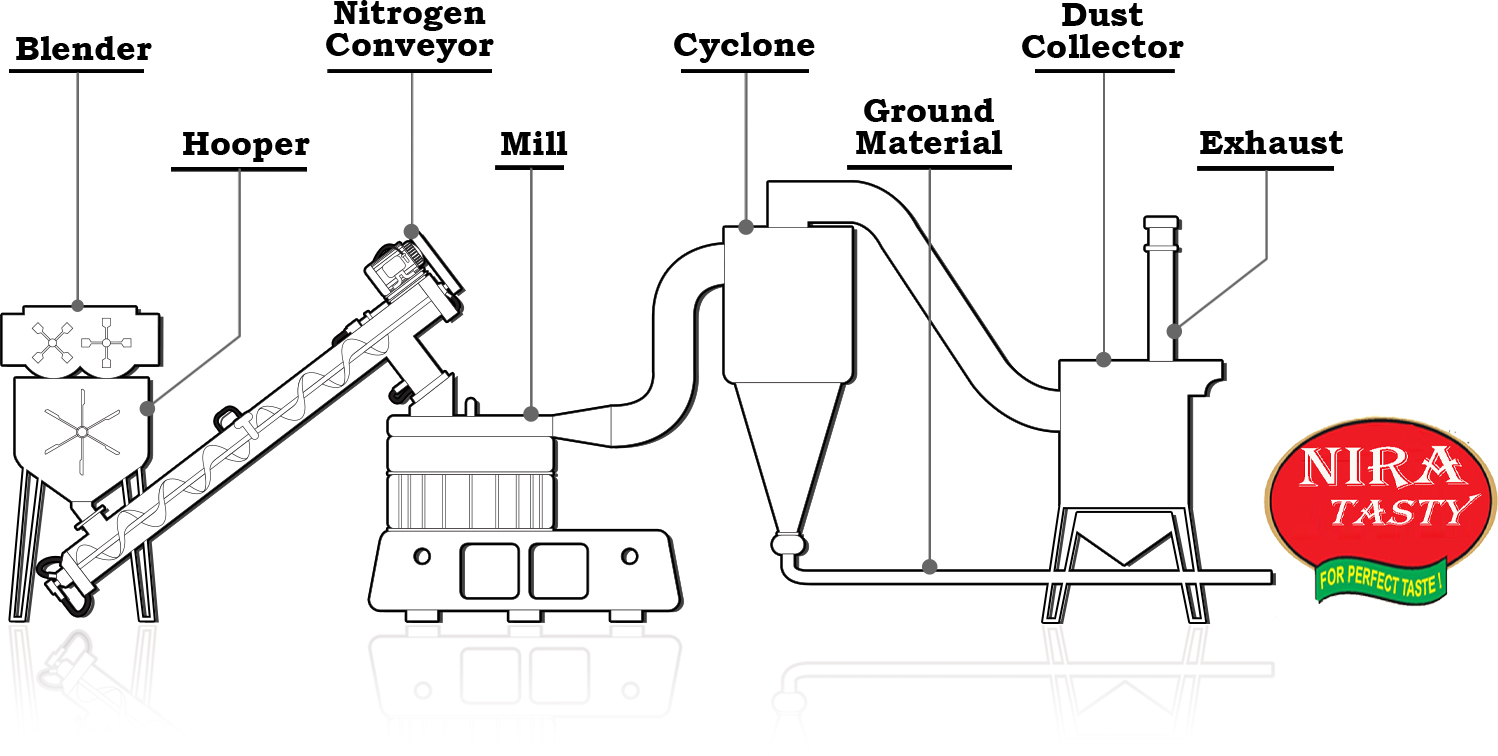

High Pressured Liquefied Nitrogen Gas is used to control grinding chamber at (-150 C) as a result loss of essential oils, minerals, olio resins and aroma can be marginally minimized. Cryogenic Grinding Technology reduces the material to particle size in less time with higher efficiency, which is difficult to attain at ambient temperature grinding in conventional grinding units.

The advantages of Cryogenic Grinding Technology with Respect to Conventional Grinding Techniques are as under:

| Cryogenic Grinding Technology | Conventional Grinding |

|---|---|

| Improves the natural Aroma by minimizing the loss of essential oils and olio resins (Approx. 3 – 10 %loss). | In Conventional Grinding Technique the loss is about 15 – 43 %. |

| Obtain finest particle size upto 50 micron (300 mesh). | Size ranges from 500 – 1000 micron (150 – 30 mesh) in Conventional Grinding Techniques. |

| Better in terms of higher natural aroma and natural colour due to lower grinding temperature. | Loss of color and aroma due to heat generated in grinding chamber. |

| Overall grinding capacity can be enhanced by 2 – 3 times as chilled process line & process equipment is not disturbed by thermal fatigue. | Lower grinding capacity at higher power consumption. |

| At Cryogenic temperature, the product at (-150 C) cools down and crystalizes at the microscopic level and hence it becomes rock solid. This crystallization locks the oils in the product and makes it easy to be ground. | While grinding, oil heats and evaporates making product dull and odorless. |

| Cryogenically processed spices have longer shelf life than the conventionally ground ones due to higher Volatile oil in them. | Due to loss of Oil, product life reduces substantially. |

| As cryogenically processed spices are rich in essential oils & olio resins, delicious recipes with higher taste and aroma can be made by adding little quantity of Hathi Spices. | Higher consumption of product. |

Infrastructure

Food Grade Manufacturing facility

In-House Ultra-Modern Laboratory

NIRA boasts a state-of-the-art, in-house laboratory equipped with advanced testing instruments to ensure unmatched product quality and safety. The facility conducts comprehensive analysis including moisture content, ash value, volatile oil, microbial load, and heavy metal testing for all spice products. Each batch undergoes rigorous inspection under the supervision of qualified professionals to maintain the highest hygiene and quality standards aligned with international norms.

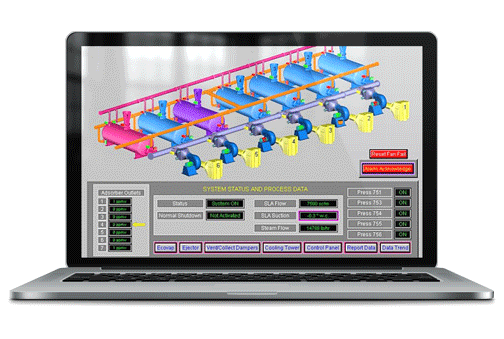

Fully Automated Plant

Our process is such that there is no external contamination, with least hand touch; Plant is controlled and monitored via SCADA and PLC systems.

Good Manufacturing Practices

Our company standard is to follow GMP. We consider it as Bhagwad Gita (holy bible)

Hygienically Packed

Packing area is centrally air conditioned, with fully automized packing machines.

Grinding Facility

Chilli

World-Class Cryogenic Grinding facility with production output of upto 2000Kg/hr. Controlled and Monitored by SCADA systems.

Turmeric

Low Temperature, Water Cooled Grinding facility. Material ground is kept cool, to avoid any loss of Volatile oil and curcuminoids. Controlled and Monitored by SCADA systems. Production capacity of 1000Kg/hr.

Coriander Cumin

Very Low Temperature and High Air Volume, Water Cooled Grinding facility. Material ground is always at room temperature, thus no loss of volatile oil. Controlled and Monitored by SCADA systems. Production capacity of 1000Kg/hr.

In-House Cold Storage:

With Storage Capacity of more than 5000 metric Tons, all raw & finished material is stored at 12° C to keep material in hygienic and safe condition.

Cryogenic Grinding

With extensive use of Liquid Nitrogen, we grind our cleaned raw material at 150* C temperature. With storage capacity of 21,000 liters of Liquid Nitrogen, we are having the largest liquid nitrogen tank in FMCG sector across India.

Blended Spices

Low Temperature, Water Cooled Grinding facility. Material ground is kept cool, to avoid any loss of Volatile oil. Production capacity of 3000Kg/hr.

ANALYTICAL

Color In Chilli

Characteristics color of the capsicum fruits are generated by the presence of pigments such as chlorophyll and carotenoids.

Capsaicin Chilli Content

The pungency of chilli is due to capsaicin and traces of allied chemicals. Pungency can be objectively evaluated by estimating the capsaicin content.

Moisture Content

Water content or moisture content is the quantity of water contained in a material.

Total Ash

The ash content is a measure of the total amount of minerals present within a food.

Curcuminoid Content in Turmeric

The curcuminoids are natural phenols that are responsible for the yellow color of turmeric.

Piperine Content in Pepper

A pungent alkaloid that is concentrated in the outer skin of pepper berries.

Volatile Oil

It is a measure of flavour and aroma of the spices.

Crude Fiber

The insoluble residue of an acid hydrolysis followed by an alkaline one. This residue contains true cellulose and insoluble lignin.

Particle size distribution (105 μ)

An index indicating what sizes of particles are present in what proportions in the sample particle group to be measured.

MICRO BIOLOGICAL

Salmonella

Food poisoning caused by infection with the salmonella bacterium. Many infections are due to ingestion of contaminated food.

Moulds

Cause biodegradation of natural materials, which can be unwanted when it becomes food spoilage.

E.coli

Can cause serious illness in humans. Infection symptoms and signs include bloody diarrhoea, stomach cramps, vomiting and occasionally, fever.

Coliforms

Group of bacteria that are used as indicators of the potential presence of pathogens, viruses or parasites in a sample.

Total Viable Count

This is a count for all bacteria, fungi, yeast & mould that will grow in aerobic condition.

Others

Yeast and fungi are normally found on wet or moist surfaces with an organic nutrient source such as aerators, screens or in nature on leaf surfaces and top soil.

PESTISIDE & Mycotoxins

Aflatoxins B1, B2, G1, G2

Naturally occurring mycotoxin. Aspergillus flavus and Aspergillus parasiticus. Aspergillus flavus is common and widespread in nature.

Organochlorines

Is an synthetic organic compound with chlorinated aromatic molecules.

Organophosphorous

They are used primarily in pest control as an alternative to chlorinated hydrocarbons that persist in the environment.

Pesticide

A substance used for destroying insects or other organisms harmful to cultivated plants or to animals.

MycoToxins

Secondary metabolites produced by microfungi that are capable of causing disease and death in humans and other animals.

Ochratoxin A

A toxic metabolite from Aspergillus ochraceu.